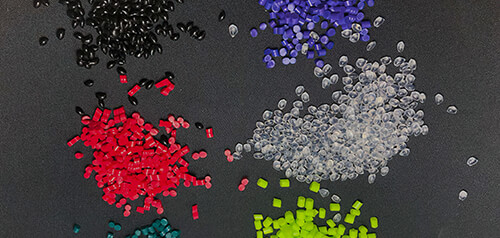

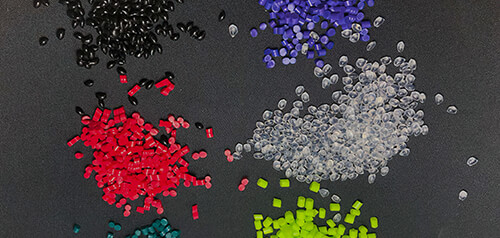

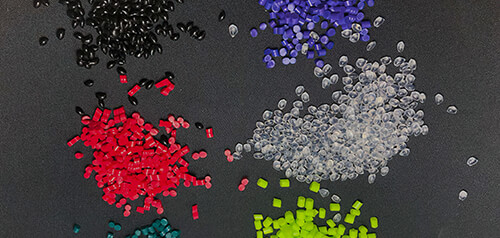

It is well known that TPE thermoplastic elastomer has the high elasticity of rubber and plastic processing properties, and can be processed by injection molding, extrusion, blow molding and so on. However, in the process of TPE injection molding, it is necessary to set the TPE injection temperature accurately, because setting the appropriate injection temperature will directly determine the quality and performance of the finished product, and may also affect the appearance of the finished product.

TPE injection

Generally, the temperature setting range of TPE products in each area is: the barrel is 160 degrees Celsius to 210 degrees Celsius, and the nozzle is 180 degrees Celsius to 230 degrees Celsius. The mold temperature should be set to be higher than the condensation temperature of the injection zone, which will avoid the contamination of the mold by moisture and the appearance of streaks on the surface of the product. Higher mold temperature usually leads to longer cycle time, but it can improve the appearance of welding lines and products. Therefore, the range of mold temperature should be designed to be between 30 and 40.

However, China Plastics believes that we should analyze the injection temperature from the perspective of TPE materials. The reference injection temperature selected for TPE and TPR materials of different compounding systems is also different. The specific needs to be adjusted and determined according to the grades provided by the TPE manufacturer and the actual processing conditions. The following is the injection temperature provided by China Plastics for different materials for reference only:

1. TPE hardness 0C~15A super soft material, injection temperature 130~200℃;

2. TPE/TPR hardness 20~110A single material injection molding material, the recommended injection temperature is 140~230℃;

3. TPE/TPR encapsulated PP, the recommended two-shot injection temperature is 170~200℃.

4. TPE/TPR encapsulated ABS, PC, the recommended two-shot injection temperature is 180~220℃.

5. TPE/TPR encapsulated PA, the recommended two-shot injection temperature is 240~270℃.

6. TPR overmolding PS (HIPS, GPPS), the recommended two-shot injection temperature is 160~190℃.

7. High-strength and high-elasticity TPE, TPR, the recommended injection temperature is 210~250℃.

8. General injection molding TPE/TPR (based on SEBS), the recommended injection temperature is 180~200℃.

What is the injection temperature of TPE? China Plastics recommends using low-temperature injection molding as much as possible, because under the premise of ensuring the quality of plasticization, the extrusion temperature is reduced as much as possible, and the injection pressure and screw speed are increased to reduce the melt viscosity to achieve the purpose of improving fluidity.