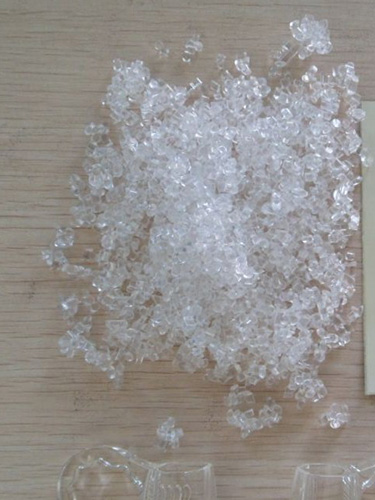

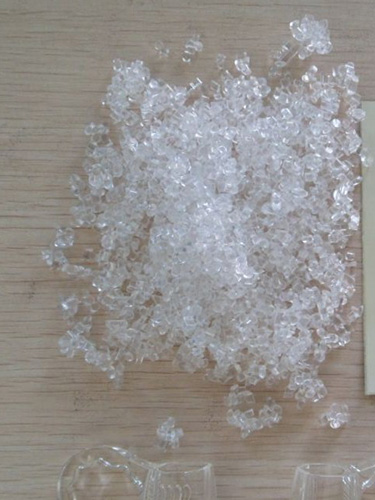

Introduction of TPE/TPR raw materials

TPE/TPR features

Our company mainly deals in Thermoplastic Elastomer (Thermoplastic Elastomer) TPE/TPR, referred to as Thermoplastic Rubber. It has elasticity, cold resistance and electrical insulation. Compared with traditional rubber, the production of thermoplastic rubber eliminates the need for banburying and vulcanization. It has easy processing, short molding cycle, high production efficiency, high product stability, and low processing cost. , Recyclable, non-polluting and other characteristics, it is a new type of material with a wide range of applications and great economic value.

TPE/TPR can be molded separately, or can be bonded with ABS, PP, PE, PS, PA, PC, ABS+PC, PMMA, POM, PA, etc. through two-shot injection to achieve a comfortable hand feel and a beautiful appearance.

TPE/TPR also has PAHS (16 carcinogens), ROHS, FDA (food grade), PHTHALATE (phthalates), ODCS (ozone layer), EN71 (heavy metals), SVHC (REACH highly concerned substances), SGS test report such as UL.

Customs number: 4002191300, primary shape styrene butadiene rubber.

Hardness range: 0 degree A-100 degree A.

Treatment before use: Bake at 70°-90° for 2 hours.

TPE/TPR use

is widely used in tool handles, diving supplies, sports equipment, casters, massage insoles, ice trays, doll toys, luggage accessories, wires and cables, sex toys, auto parts, stationery, environmental protection films, elastic tubes, and seals.