TPU material introduction

TPE/TPR features

It is a thermoplastic polyurethane elastomer, the hardness distribution range is between 60A~75D,

It is a widely used green and environmentally friendly material, and its use worldwide is increasing day by day and continues to develop

•Wide processability, suitable for molding processes such as injection, extrusion, calendering, and blowing

•Good oil resistance, can overcome the shortcomings of rubber materials

•Excellent low temperature resistance, processed products can be applied in any area

• Extremely high wear resistance, excellent mechanical properties, is the best of all TPE materials

•Excellent elasticity and softness, good noise reduction and shockproof effect

•Environmentally friendly material, recyclable

TPU application introduction

•TPU is widely used in sports equipment, sports shoe accessories, gears, wires and cables, watch straps, industrial belts, fire hoses, film, laminates, conveyor belts, ropes and other industrial products.

• It can be bonded with ABS and PC materials. It is suitable for mobile phone accessories, USB covers, mobile phone shell encapsulation, mobile phone protective covers, Bluetooth speakers, earphone accessories and other communication equipment in the electronic and electrical industry.

•At the same time meet and have PAHS (16 carcinogens), ROHS, FDA (food grade), (phthalates), ODCD (ozone layer), EN71 (heavy metals), (REACH highly concerned substances), halogens, ASTM F963, UL, California 65 and other test reports, and can be recycled and reused, which is environmentally friendly.

TPU main production raw materials

Main raw materials

•Isocyanates:

MDI, TDI, IPDI, H12MDI

•Long chain glycols:

Ethylene glycol, butylene glycol, adipic acid, PTMEG, PPG, polycarbonate and polyhexanone

Lactones

•Short-chain glycol:

Ethylene glycol, 1.4 butanediol, etc.

Additives

Antioxidant, anti-yellowing agent, slip agent, foaming agent, etc. and other special demand additives

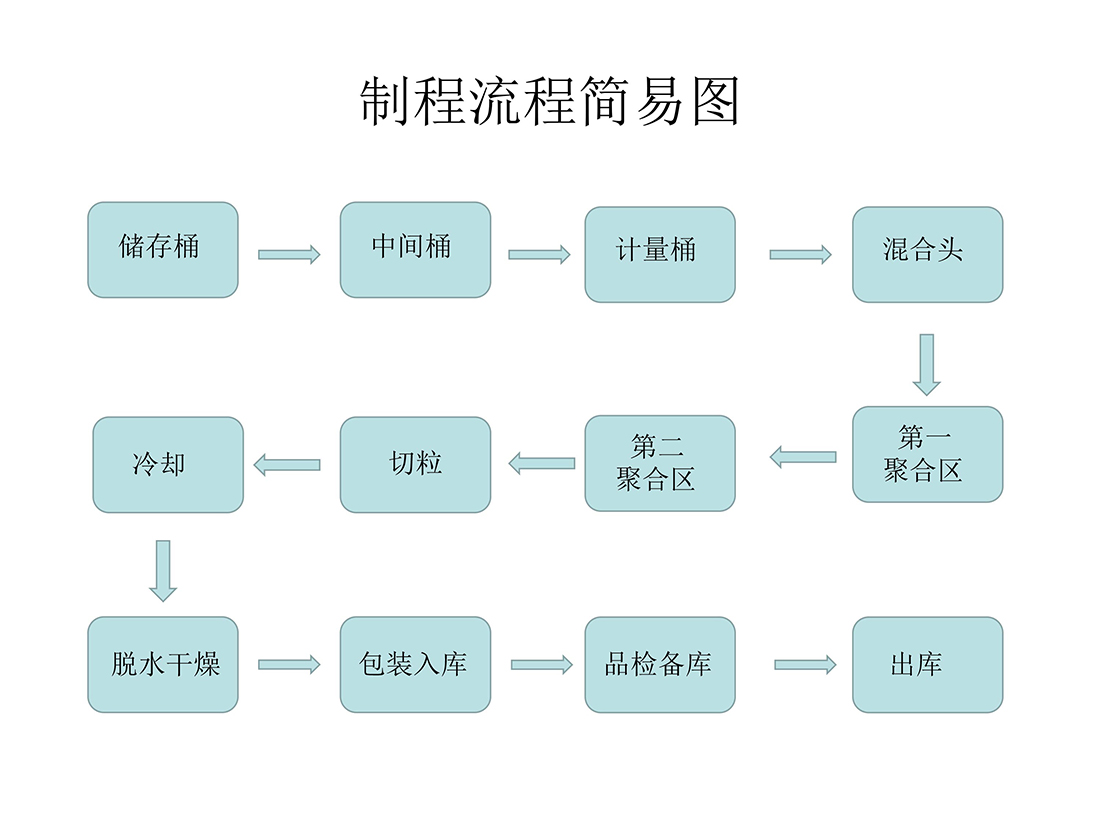

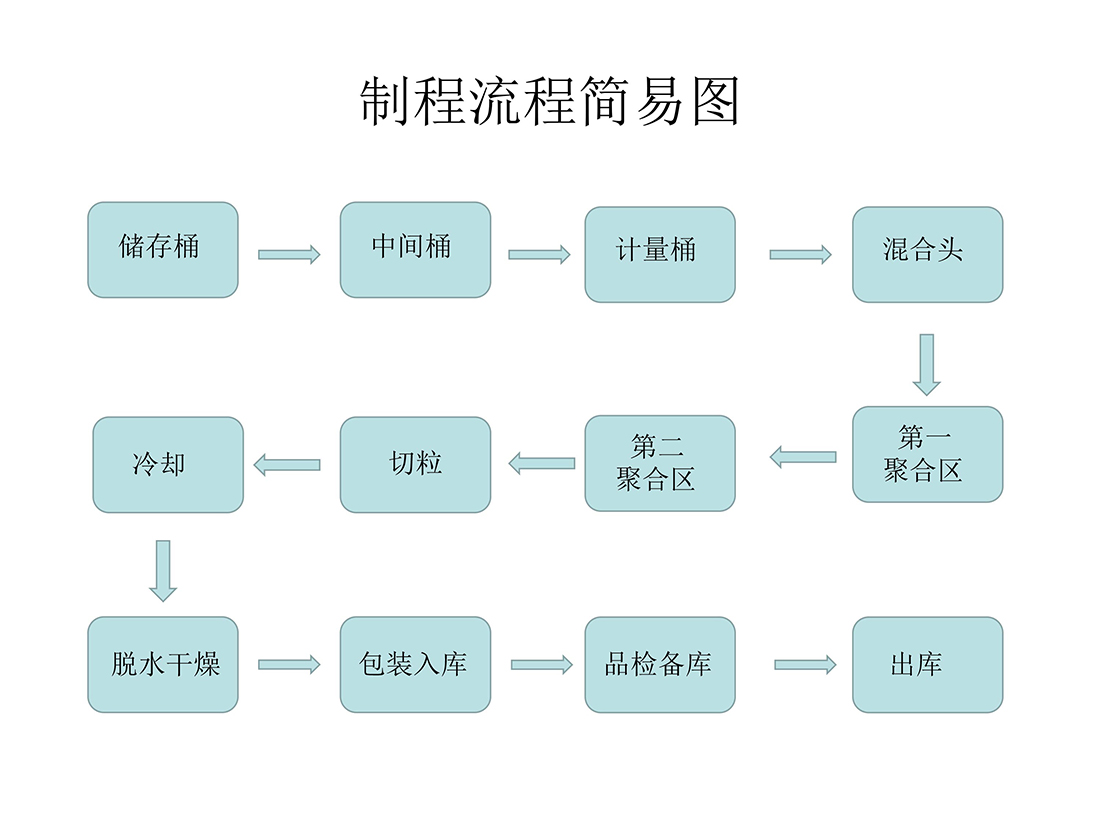

TPU process introduction

• The manufacture of TPU is slightly divided into three categories:

Batch method, semi-continuous method and continuous method

•Batch method

Small equipment investment, low output, unstable quality

•Semi-continuous method

Between the two, but it is suitable for this process when there are special products.

•Continuous method

Large equipment investment and stable quality, but more advanced process engineers are required

"Mier" mainly deals in TPU material series

•Polyether TPU--Excellent hydrolysis resistance

•Polyester TPU--widely used and cost-effective

•Anti-UV TPU--Customize different anti-UV grades TPU according to customer requirements

• Aliphatic TPU-never yellowing grade, high cost

• Conductivity TPU-can stick ABS/PC, according to customer requirements to make different conductivity index

• Antistatic TPU--Meet the surface resistance value of 106~1012 power, and can provide various color schemes at the same time.

•Fireproof TPU-halogen-free environmental protection, customized different fireproof grades

• Low hardness TPU-foaming grade

Features of Mier TPU

High anti-yellowing TPU material, main application: mobile phone protective cover.

To meet customers’ needs for high transparency, low precipitation risk, and high resistance to UV yellowing, “Mier’s mobile phone jacket TPU material is now being supplied to Huawei, OPPO and other mobile phone manufacturers, as well as Apple, Samsung and other accessory manufacturers, which can meet related variable temperature storage. . QUV ultraviolet, solar radiation, high and low temperature cycle and other related environmental testing standards.

Low dielectric constant TPU materials, main applications: mobile terminal equipment such as mobile phones, jackets/outsides.

With the technological revolution of 5G communication, the 5G network era of mobile terminal equipment has been changing with each passing day, and mobile phone housing materials are also required to be materials that are not easily affected by electric waves. "Mi'er" has developed a low dielectric constant TPU material through the recombination of the main component of TPU polyol resin.

Antibacterial TPU materials, main applications: antibacterial TPU for mobile phone jackets, and antibacterial TPU for smart bracelets.

After experiencing the new crown epidemic, Mier Plastic Materials developed an antibacterial series of TPU materials. On the basis of maintaining the original performance, the antibacterial function of the material was increased, and the antibacterial rate against Escherichia coli reached 99.9%.

Skin-friendly TPU materials for smart wearable devices. Main applications: smart bracelets, smart watches, VR devices, etc.

For electronic products with high requirements on the surface touch of the material, there is no need to spray to achieve a skin-friendly touch, which increases the user experience of consumers. "Mier" skin-friendly series TPU materials can meet IS0 10993 related anti-skin allergy test report, anti-mold test, free color migration, low precipitation, and can meet the characteristics of two-color injection molding and multi-material molding process.

Antistatic TPU material, main application: special handheld mobile terminal equipment/special equipment with explosion-proof requirements.

According to the needs of customer application scenarios, we can develop targeted antistatic surface resistance in the range of 106~1012, and correspondingly meet the multi-material injection molding program (bonding ABS/PC/PC segment ABS alloy/PA, etc.).

Bio-based TPU materials, main applications: reactive hot melt adhesives/hot melt adhesives, injection molding/extrusion products.

In response to the global environmental protection policy, "Mier" has developed a series of bio-based TPU materials, in which the content of renewable materials is 28%-46%, and the relevant models can meet the requirements of food regulations, UV stability, degradable regeneration and other performance requirements.

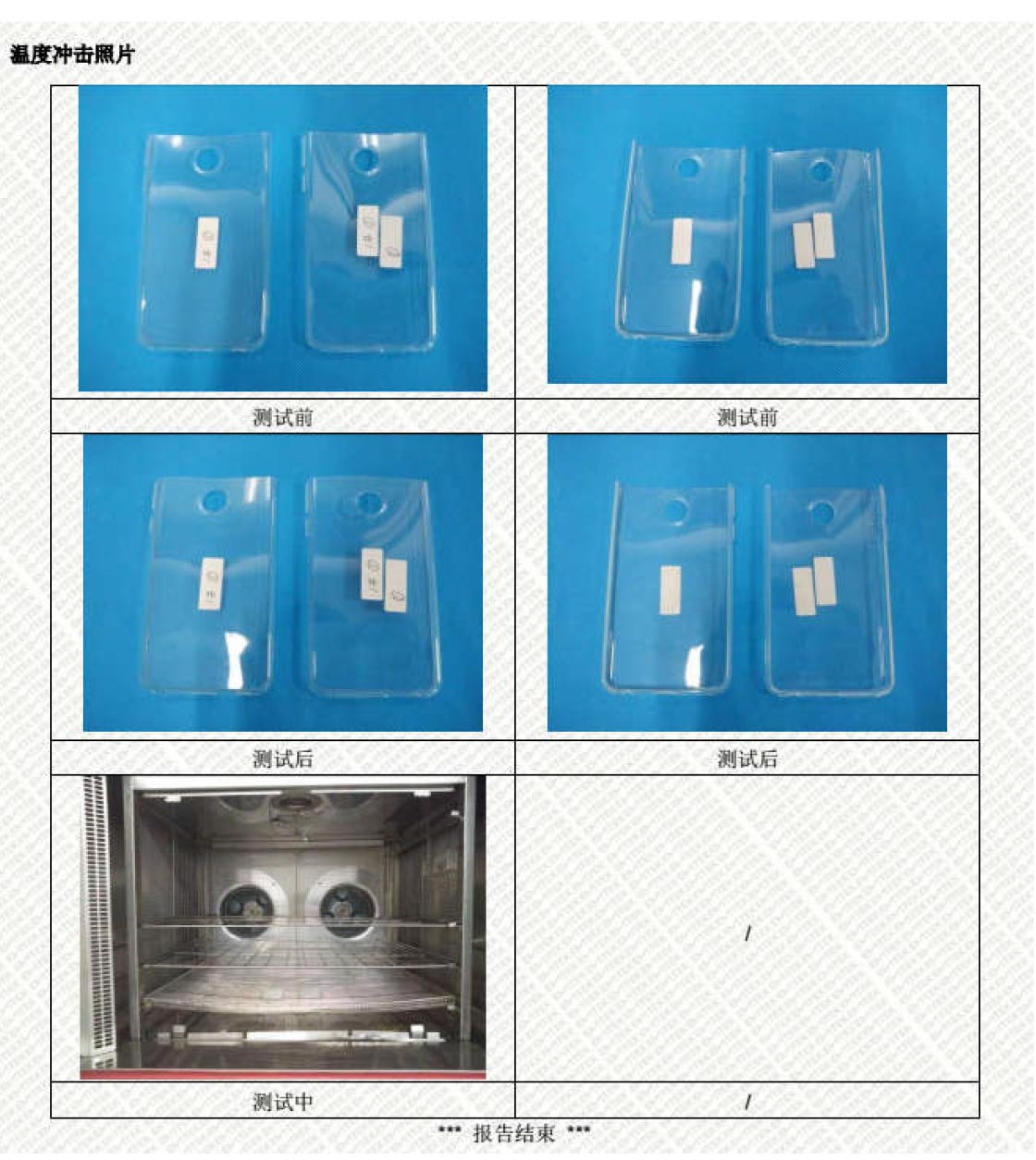

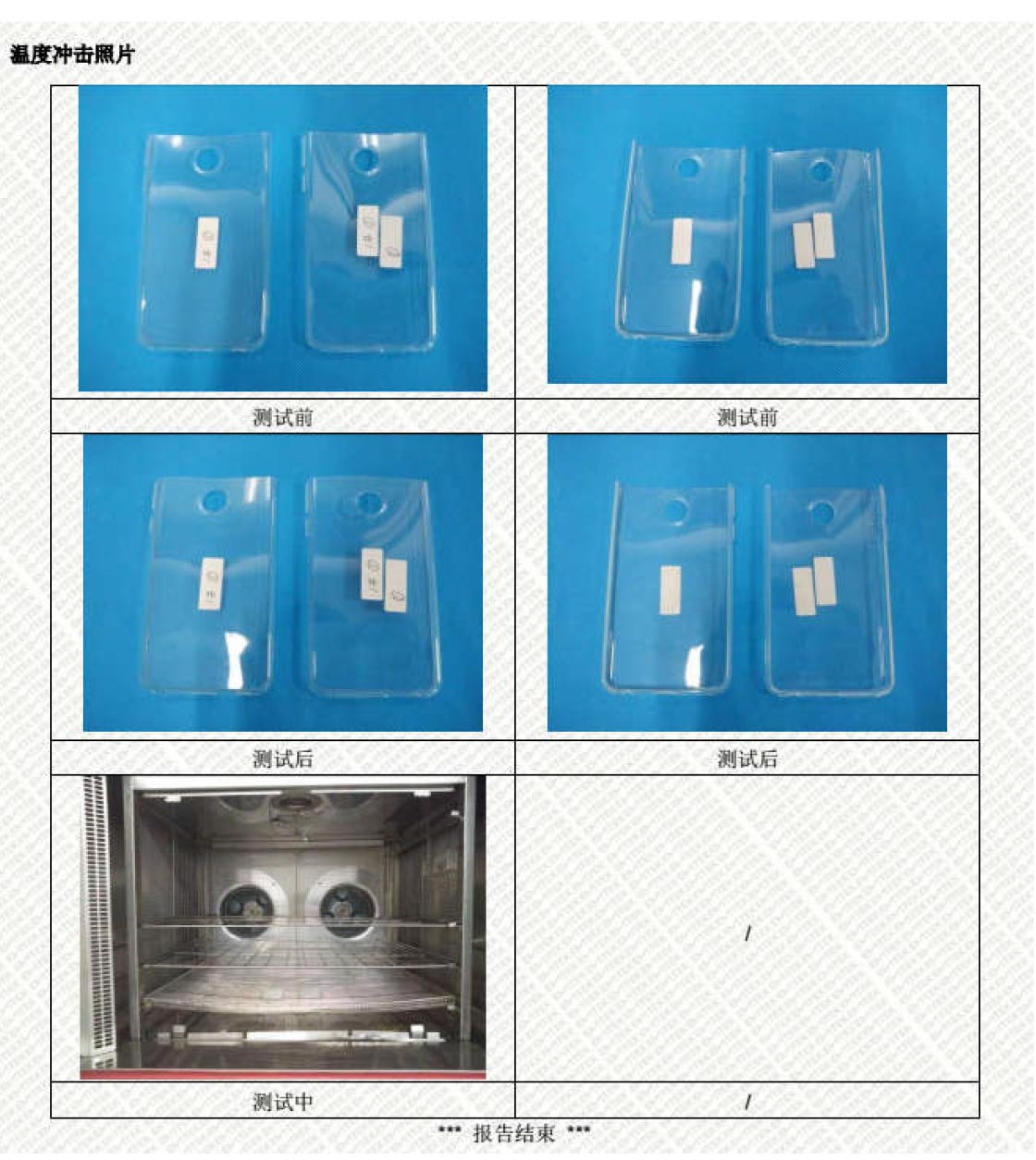

Mainly introduce anti-UV/TPU materials

UV is the abbreviation of ultraviolet. The full English name is ultraviolet. The wavelength is 10~400nm. It has a strong penetrating power, can penetrate most transparent glass and plastics, and cause aging effects on the material. The intuitive perception is that the material is yellow. Change, the same TPU is no exception. In order to make products made of TPU material have a longer service life, "Mier" has been committed to researching and developing TPU materials with higher UV resistance for many years and has made certain research results.

"Mier" UV-resistant TPU material test report result:

|

"Mier" Introduction to the basic physical properties of UV-resistant TPU models

|

|

Grade

|

Hardness A

|

Modulus Kg/cm

|

Modulus Kg/cm

|

Tension resistance Kg/cm

|

Elongation %

|

Friction loss Mg

|

backlash flexibility %

|

|

MRI-95AY-3

|

95 soil 3A

|

125adhesiveABS /PCseries

|

185

|

400

|

530

|

40

|

30

|

|

MRI-90AU-5

|

90士3A

|

130

|

|

|

Recommended molding process parameters

|

|

Inlet section

|

Compressed section

|

Measuring section

|

Relay

|

die head

|

|

190~195

|

195~205

|

205~215

|

215~220

|

215~220

|

|

Pre-treatment: 90"C baking 2~ 4h

|

"Mier" TPU anti-UV test report display